ABOUT FLEXBARK

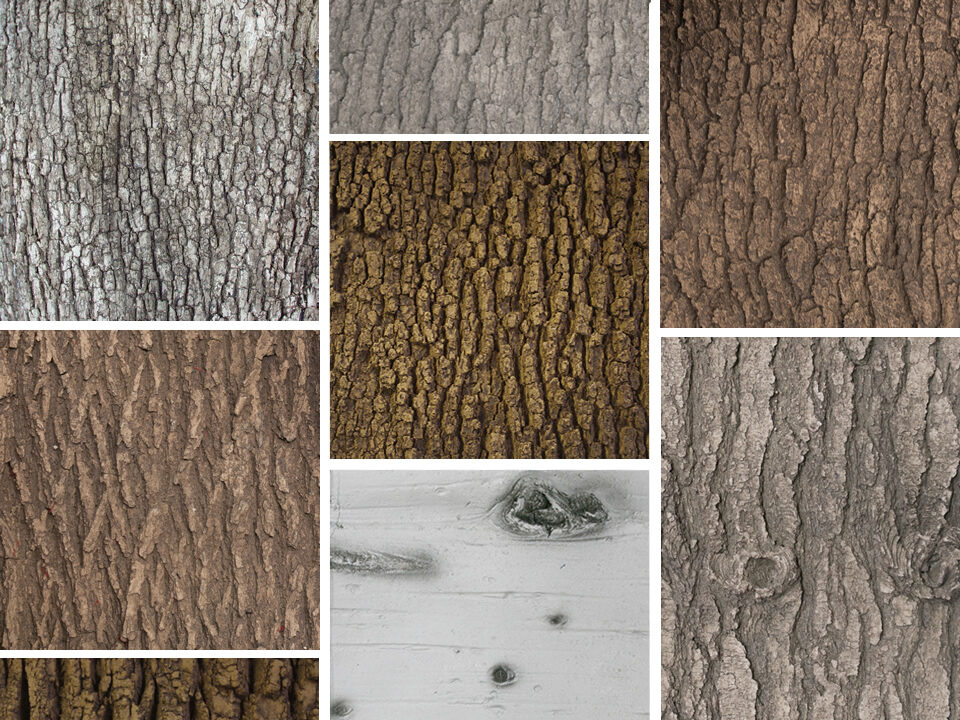

The FLEXBARK division operates the state-of-the-art replication of artificial (or faux) tree bark and trees developed by Replications Unlimited. It is the result of a unique polyurethane elastomeric material and an innovative production process to create the most realistic flexible faux bark available. Now flexible faux bark can be quickly created with texture and coloring so realistic it can easily fool the best botanist.